KCSE Past Papers Power Mechanics 2011

Click Here - Free KCSE Past Papers » KCSE Past Papers Power Mechanics 2011 » Free Downloads » KCSE Papers & Marking Schemes

4.7.1 Power Mechanics Paper 1 (447/1)

SECTION A (40 marks)

Answer all the questions in this section.

1 (a) Name two areas in a power mechanics workshop which require ventilation. (1 mark)

(b) Name two automotive trade courses offered at the Directorate of Industrial Training. (1 mark)

2 (a) Sketch a countersunk rivet and label two main parts. (2 marks)

(b) Use sketches to differentiate between Acme and butress type of screw thread. (2 marks)

3 (a) State the two major classifications of greases. (1 mark)

(b) (i) State the meaning of the term volatile as applied to materials.

(ii) Give two examples of volatile materials. (2 marks)

4 (a) State the meaning of each of the following engine terminologies:

(i) bore;

(ii) throw;

(iii) volumetric efficiency.

(3 marks)

(b) State two functions of the charging system in an engine. (2 marks)

5 (a) Name three checks that must be carried out when fitting new piston rings on a dismantled single cylinder engine piston. (3 marks)

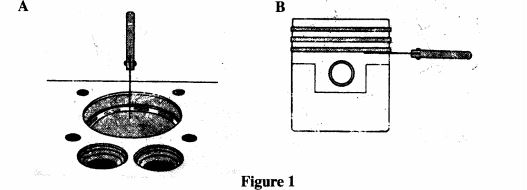

(b) Figure 1 shows two measurements A and B performed as an engine component.

Name the measurement, the component and the tool used in each case. (3 marks)

6 (a) State the function of each of the following components in a vehicle electrical circuit:

(i) diode;

(ii) relay. (2 marks)

(b) State four possible causes of engine backfiring. (2 marks)

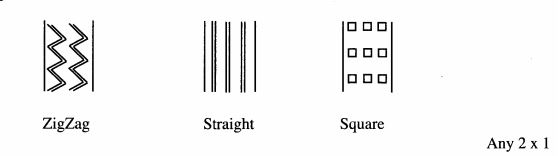

7 (a) Sketch and name two types of tyre tread patterns. (2 marks)

(b) List four different components that are involved in absorbing shock when a vehicle hits a bump. (2 marks)

8 (a) State the meaning of each of the following as used in hydraulic braking system:

(i) Bleeding;

(ii) Flushing. (2 marks)

(b) Figure 2 shows a simplified drawing of a steering system.

Name the parts labelled A to D. (2 marks)

9 (a) Name two types of vehicle rear axles. (1 mark)

(b) Differentiate between dead and live axles. (2 marks)

10 (a) State how the size of each of the following tools is determined:

(i) open end spanner;

(ii) ball pein hammer. (2 marks)

(b) Make a freehand drawing of straight snips and label two main parts. (3 marks)

SECTION B (60 marks)

Answer question 11 and any other three questions from this section.

Candidates are advised to spend not more than 25 minutes on question II.

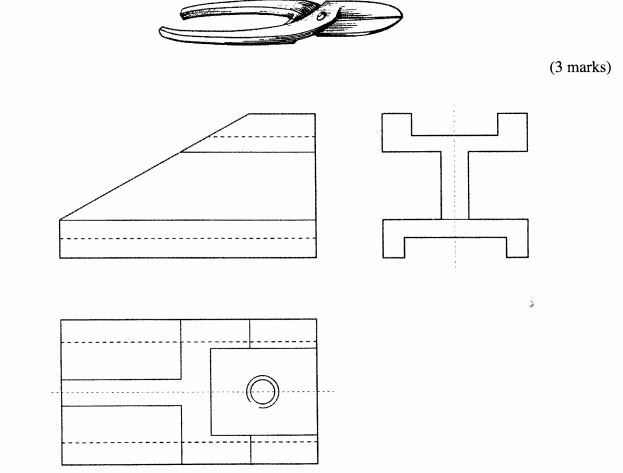

11 Figure 3 shows an isometric drawing of an engine mounting. Draw, full size in first angle projection the following views:

(a) Front elevation in the direction of arrow A;

(b) End elevation;

(c) Plan. (15 marks)

12 (a) Name four types of fuel used in motor vehicle engines. (2 marks)

(b) Figure 4 shows the layout of a compression ignition engine fuel system.

(i) Name the parts labelled U, V, W, X, Y and Z. (3 marks)

(ii) Explain how the system operates. (10 marks)

13 (a) Explain the use of the following units in a propeller shaft:

(i) universal joint;

(ii) slip joint. (2 marks)

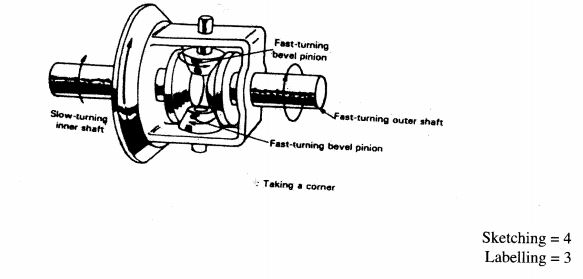

(b) With the aid of a labelled diagram, explain the operation of a differential unit when a vehicle is taking a tum. (13 marks)

14 (a) State three advantages of disc brakes over drum brakes. (3 marks)

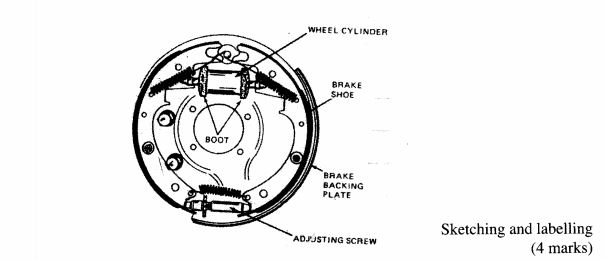

(b) With the aid of a labelled diagram, describe the construction of the drum brakes assembly. (12 marks)

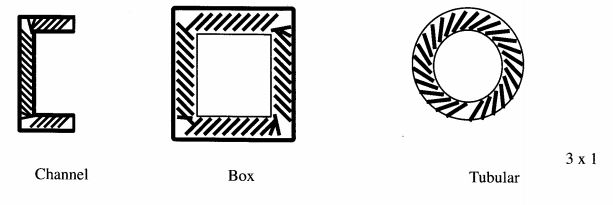

15 (a) Illustrate the following frame sections used in a motor vehicle:

(i) channel;

(ii) box;

(iii) tubular. (3 marks)

(b) Describe four types of car bodies. (6 marks)

(c) Explain the three methods of checking minor chassis frame misalignment.

4.7.2 Power Mechanics Paper 2 (447/2)

STATION 1

The figure below shows a truncated air cleaner assembly‘ On the drawing paper provided, sketch in good proportion the exploded view of the assembly and label four parts.

(10 marks)

STATION 2

Using the tools, equipment and materials provided, make the support bracket as shown in the figure below.

(10 marks) STATION 3

(a) Identify the substances in the containers labelled V to Z and state the use of each in motor vehicle servicing. (5 marks)

(b) Identify the fasteners labelled P to T and state a feature that makes each fastener unique in its class. (5 marks)

STATION 4

Using the tools provided, determine the compression ratio of the given engine. Take the clearance volume to be 30 c.c. (10 marks)

STATION 5

State the name, class and use of the tools provided labelled A to E as shown in the table below. (10 marks)

STATION 6

Using the tools and materials provided, make the flange gasket to fit the given water pump. (10 marks)

STATION 7

Name the vehicle parts labelled F, G, H, J and K. For each pan, identify one defect, state two possible effects and complete the table below. (10 marks)

STATION 8

Using the tool materials and components provided, connect the starting circuit of a vehicle. (10 marks)

STATION 9

For the tyre provided:

(a) Identify and record the following:

(i) Maximum load

(ii) Maximum inflation limit

(iii) Type of construction

(iv) Tyre size

(v) Rim size

(vi) Date of manufacture

(3 marks)

(b) Identify the defect at the section marked X and state one possible cause of the defect.

DEFECT ....................

POSSIBLE CAUSE ...........

(2 marks)

(c) Demonstrate to the examiner how to measure the following:

(i) inside diameter

(ii) Height ..............

(iii) Width ..............

(iv) Tread depth ..... ..

(v) Tread width...........

(5 marks)

STATION 10

(a) Using the multicylinder engine provided, demonstrate to the examiner how to identify the misfiring cylinder. (6 marks)

(b) State:

(i) two possible causes of the misfiring in (a) above. (2 marks)

(ii) how each cause in (b)(i) above is determined. (2 marks)

24.0 POWER MECHANICS (447)

24.1 Power Mechanics Paper 1 (447/1)

1. (a) Workshop areas

Charging area

Spraying/ painting

Soldering/Welding

Storage for volatile materials Any 2 X 1/2

(b) Trade courses at DIT

General mechanics

Panel beating

Auto-electrics

Spraying

Uphostery and interior decoration Any 2 X 1/2

2. (a) Countersink Rivet

3. (a) Greases

(i) Soap base

(ii) Number base (2 x 1/2 marks)

(b) Volatile: Substances which readily turn to vapour at a relatively low temperature. (1 x 1)

e.g. petrol, cellulose, thinners, paint, spirits. Any 2 x 1/2

4. (a) Terminology

(i) Bore: Is the diameter of an engine cylinder.

(ii) Throw: Is the distance between centreline of the crankshaft and the centreline of a crankpin.

(iii) V. E: ls the amount of air drawn in a cylinder divided by the actual volume of the cylinder. (3 X 1 marks)

(b) Charging System

(i) Restores back into the battery the current used to start an engine.

(ii) Handles the load of lights, ignition, radio and other circuits when engine is running.

5 (a) Checks on Connecting Rod

Rod side clearance

Big end for wear

Rod alignment for out of round

Bushings for wear and scoring

(b) Measurements

A: Ring gap, piston ring, feeler gauge

B: Side clearance, piston ring, feeler gauge

6 (a) Electrical component

DIODE converts AC produced by alternator to DC

RELAY is a magnetic switch used in various electrical circuits.

(b) Engine Backfiring Wrong ignition timing - Carbon deposits

Wrong S.P. range - Overheating

Too lean mixture - Faulting condenser

Too rich mixture

7 (a) Types of Thread Patterns

(b) Absorbing shocks

Car tires

Shock absorbers

Spring in vehicle seats

Suspension springs

8. (a) Meaning

Bleeding is the process of removing trapped air in braking system

Flushing is the process of removing old/used fluid from the system.

(b) Steering system

A Track rod

B Steering gear box

Steering arm

Idler arm

9. (a) Rear Axles

Semi-floating

Three quarter floating

Full floating Any 2 x 1/2

(b) Live axle transmits

While dead axle doesn’t transmit

10. (a) Tool sizes

Spanner is the distance between the two jaws

Hammer is the weight of the head (2 x 1)

(b) Straight snips(3 marks)

11.

12. (a) Petrol

Diesel

Gasohol

Liquidified petroleum gas

(4 x 1/2 = 2)

(b) (i) Fuel tank -U

Course filter -V

Lift pump -W

Fine filter (s) -X

Injector pump -Y

Injectors -Z

(6 X 1/2 = 3)

(ii) Operation

As the engine crankshaft rotate, a low pressure (depression) is created in the chamber of the lift pump. This creates a pressure difference between the pump chamber and the tank, thereby causing fuel to be drawn into the lift via the course filter. The course filter removes large dirt particles from the fuel.

As the crankesraft continues to rotate, the lift pump then applies a higher pressure to the fuel and forces it through the fine filters to the galleries of the injector pump. The fine filters remove any remaining fine particles from the fuel because diesel requires to be extremely clean.

The injector pump accurately meters the right amount of fuel to each injector nozzle and also pumps it at very high pressure at the end of each compression stroke, and in accordance with the firing order.

Each injector atomises the fuel and sprays it to the compressed air in each cylinder, thereby causing combustion to take place.

Due to the very pressures in the system, some fuel always escapes back past the injector nozzles. This is collected by the leak-off pipes and is returned either to the tank to the intake side of the fine filter.

(10 marks)

13. (a) (i) Universal Joint compensates for change in drive shaft angle.

(ii) Slip joint compensates for change in drive shaft length. (2 x 1 marks)

(b) Operation of Differential unit when cornering.

Cornering

When taking corners, the resistance on the rotation of the inner axle bevel gear increases as the wheels turn at different speeds. This causes the differential pinion gears to tum on their own axis and roll around the axle bevel gears. When this happens the inner wheel axle gear slows down. This causes the pinion gear to ‘walk’ around the slower turning axle bevel gear.

This results in additional rotary motion being transmitted to the outer axle bevel gear causing the axle shaft to turn faster but still providing equal power to both wheels.

In some cases one of the driving wheels can have little or no traction, the torque required to tum the wheel without traction being very low. The wheel with good traction is in effect holding the axle bevel gear on the that gear side stationery.

Consequently, the differential pinion gears ‘walk’ around the stationary side axle bevel gear and drive the other wheel at twice the speed This the wheel with no tranction be essentially slipping. A whee] with no traction cannot deliver torque, hence, all the turning effort goes to the slipping wheel. To counter wheel slippage, non-slip differential or differential locks are used.

(6 x 1 marks)

14. (a) Advantages of disc brakes

Greater heat dissipation

Cleaner braking surfaces

Lighter in weight

Simpler construction hence easier to service

Any 3 x 1

(b) Construction of drum brake assembly

The assembly comprises the following:

(1) Brake Drum made of iron and bolted to the wheel to rotate together. (2 marks)

(ii) Backing plate made of steel and covers the show assembly. (2 marks)

(iii) Shoe assembly comprising two shoes, wheel cylinder, springs, adjusting screws and anchor plate. (2 marks)

(iv) Wheel cylinder fitted between the ends of the shoes to activate them when brakes are applied. (2 marks)

(v) Springs, linkages and fasteners.

Total marks for explanation = 8

15. (a) Frame Sections

(b) Types of Car Bodies

(i) Saloon (sedan) has closed body with four doors.

(ii) Station wagon (estate) has extended roof to the rear and folding rear seat to create space for luggage.

(iii) Coupe (sport) has closed body with two doors and lowered roof towards the back.

(iv) Convertable (drop head) closed car that can be opened by removing or lowering the roof.

Naming 4 x 1/2

Description 4 x 1

(c) Checking minor misalignment

(i) Wheel base check

- Set front wheels in the straight position

- Check wheel base on each side

(2 marks)

(ii) Alignment

- Check to ensure rear wheels are parallel to each other

- Hold straight edge against the rear wheel

- Turn the front wheel until parallel to straight edge

- Do the same for both sides

(iii) Plumbline check

- Drop plumbline from both sides of each shackle of the spring and mark on the floor with chalk for all the 8 points.

- Join the chalk marks diagonally

- If frame is aligned, all the diagonals should across at the centre line.

Naming 3 x 1

Description 3 x 1

Kenya Scholarships for Undergraduate Students » Kenya Scholarships for Postgraduate Students » Undergraduate Scholarships for Kenyan Students » Kenya Undergraduate Scholarships » Full Undergraduate Scholarships for Kenyans » Kenya Postgraduate Scholarships » Scholarships & Grants » Undergraduate Scholarships » Universities in Kenya » Kenya Universities and Colleges Central Placement Service (KUCCPS) » Colleges in Kenya » KASNEB Registration & Results » Secondary Schools Scholarships in Kenya » Undergraduate & Graduate Scholarships for Kenyans

Scholarships for African Students » Undergraduate Scholarships » African Women Scholarships & Grants » Developing Countries Scholarships » Erasmus Mundus Scholarships for Developing Countries » Fellowship Programs » Funding Grants for NGOs » Government Scholarships » LLM Scholarships » MBA Scholarships » PhD and Masters by Research Scholarships » Public Health Scholarships - MPH Scholarships » Refugees Scholarships » Research Grants » Scholarships and Grants

Scholarships in Australia » Scholarships in Belgium » Scholarships in Canada » Scholarships in Germany » Scholarships in Italy » Scholarships in Japan » Scholarships in Korea » Scholarships in Netherlands » Scholarships in UK » Scholarships in USA

Scholarship 2026/27

Current Scholarships 2026/2027 - Fully Funded

Full Undergraduate Scholarships 2026 - 2027

Fully Funded Masters Scholarships 2026 - 27

PhD Scholarships for International Students - Fully Funded!

Funding Opportunities for Journalists 2026/2027

Funding for Entrepreneurs 2026/2027

***