KCSE Past Papers Metalwork 2011

Click Here - Free KCSE Past Papers » KCSE Past Papers Metalwork 2011 » Free Downloads » KCSE Papers & Marking Schemes

4.5.1 Wood Work Paper 1 (445/1)

SECTION A (40 marks)

Answer all the questions in this section.

1 (a) State four causes of accidents when using a cold chisel. (2 marks)

(b) State the minimum entry requirement for each of the following courses:

(i) artisan;

(ii) diploma;

(iii) craft. (1 1/2 marks)

2 (a) Outline the procedure of reading a micrometer. (2 marks)

(b) State four uses of a scribing block. (2 marks)

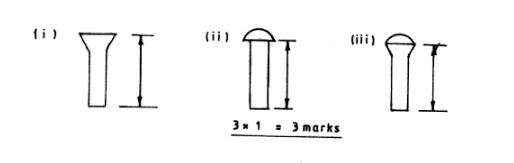

3 (a) Use sketches to show the length of each of the following rivets:

(i) countersunk head;

(ii) round head;

(iii) raised countersunk. (3 marks)

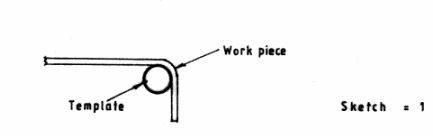

(b) Use labelled sketches to show two uses of a template. (3 marks)

4 Name a suitable material and state the property that makes it appropriate for making each of the following:

(a) twist drill bit;

(b) rivet;

(c) head of ball pein hammer;

(d) kitchen knife blade. (4 marks)

5 (a) With reference to filing explain:

(i) the term pinning;

(ii) how pinning is prevented;

(iii) how pinning is treated. (3 marks)

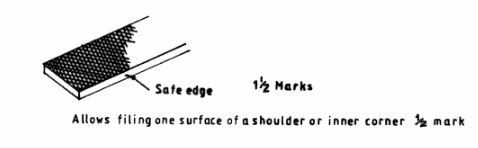

(b) (i) Use a labelled sketch to show the safe edge of a file.

(ii) State the function of the safe edge of a file. (2 marks)

6 (a) State two advantages of a leg vice over engineer’s vice. (2 marks)

(b) Outline the procedure of locating the centre of a round bar using the centre head and the rule of a combination set. (2 marks)

7 (a) State two forms in which filler metal for brazing is manufactured. (1 mark)

(b) Give one reason for manufacturing filler metals in different forms. (1 mark)

8 (a) Explain the term welding. (1 mark)

(b) State two advantages of rightward welding over leftward welding. (2 marks)

9 Describe the process of oil blanking as applied to metal finishing. (3 marks)

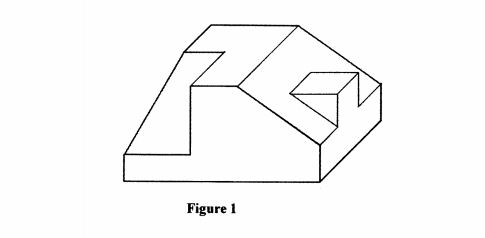

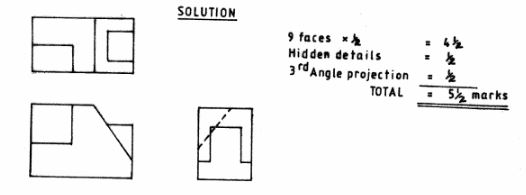

10 Figure 1 shows an oblique drawing of a block.

Sketch in third angle projection the three orthographic views of the block. ( 5 1/2 marks)

SECTION B (60 marks)

Answer question 11 and any other three questions from this section.

Candidates are advised to spend not more than 25 minutes on question 11.

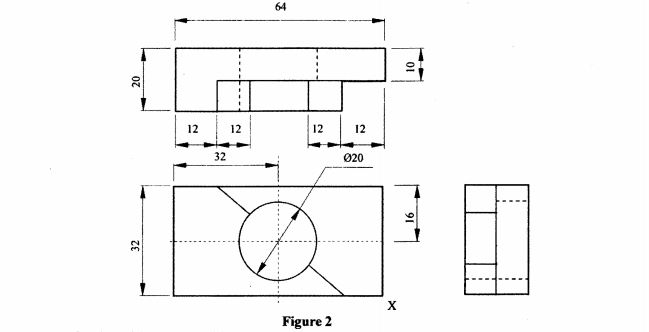

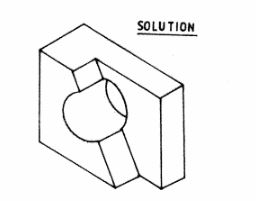

11 Figure 2 shows orthographic views of a machined block drawn in third angle projection.

On the grid paper provided, draw the isometric view of the block taking X as the lowest point.

Show three leading dimensions. (15 marks)

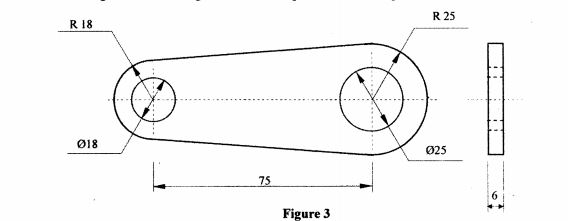

12 (a) Figure 3 shows a link to be made of 6 mm thick mild steel. Outline the procedure of making the link naming all the tools required in each step. (6 marks)

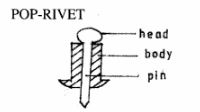

(b) (i) Sketch a pop rivet and label its parts.

(ii) List three steps involved in preparing work pieces for pop riveting.

(iii) With the aid of sketches, outline the procedure of pop riveting. (9 marks)

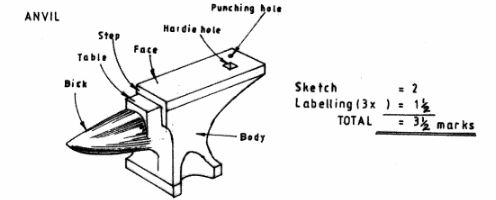

13 (a) Sketch an anvil and label three parts. (3 marks)

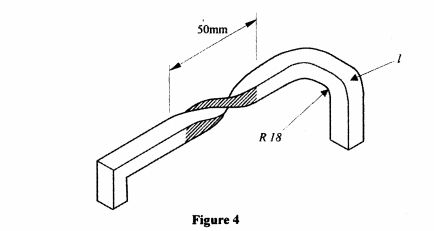

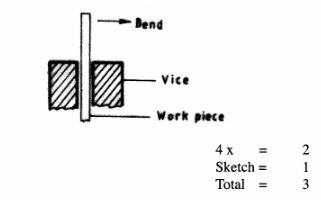

(b) Figure 4 shows a portion of an arm bar made from a 6.0 mm square mild steel rod.

(i) Determine the length of the material required to form the bend labelled l.

(ii) With the aid of sketches, outline the procedure of making the arm bar. (11 1/2 marks)

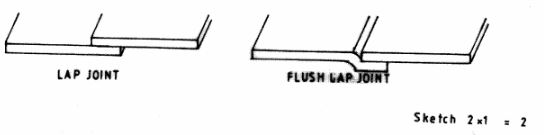

14 (a) Use sketches to show the difference between a lap joint and a flush lap joint. (2 marks)

(b) Outline the procedure of sweating as applied to soft soldering and name all the tools and materials required in each step. (8 marks)

(c) Give four safety precautions to be observed when soldering. (2 marks)

(d) State three reasons why copper is preferred in making head of a soldering iron. (3 marks)

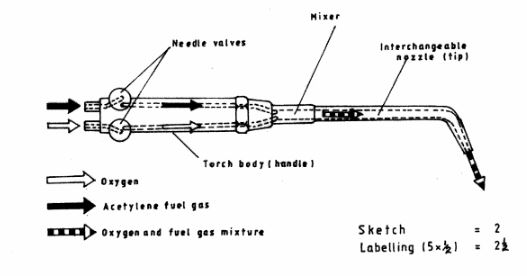

15 (a) Sketch a gas welding torch and:

(i) label five parts;

(ii) state three precautions to be observed when handling it. (7 1/2 marks)

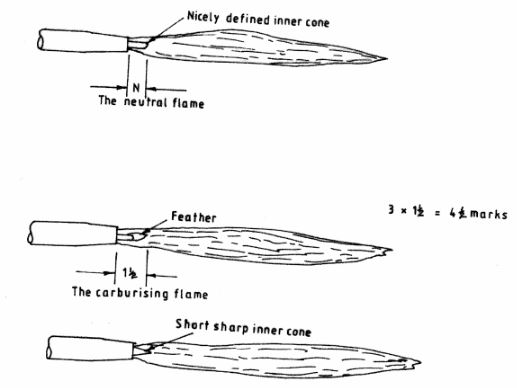

(b) (i) Use labelled sketches to show the three types of gas welding flames.

(ii) Explain how each of the flames is obtained. (7 1/2 marks)

22.0 METAL WORK (445)

22.1 Metal Work Paper 1 (445/1)

1. (a) CAUSES OF ACCIDENTS

Failure to hold chisel firmly

Failure to use goggles

Using chisel with mushroomed head

Using blunt chisel

Failure to hold work piece firmly

Grieared chisel .

Any 4 x 1/2= 2 marks

(b) ENTRY REQUIREMENT

(i) ARTISAN KCPE

(ii) DIPLOMA KCSE (C Plain) or Craft certificate

(iii) CRAFT KCSE (D Plain) of Artisan

2. (a) READING MICROMETER

Read the whole number on barrel/ sleeve

Read complete subdivision on barrel

Read number on thimble before datum line

Read extra

divisions coinciding with datum line

Finding the centre of the round bar.

(b) SCRIBING BLOCK

Marking out

Testing parallelism

Testing alignment

Testing roundness/concentricity 4 X 1/2= 2 marks

3. (a)

(b) Marking + appropriate sketch

Checking + sketch

Guiding + sketch All) 3 X 1= 2 marks

4. (a) Twist drill HSS/HCS Hardness and wear resistance

(b) Rivet MS, Alminium, Brass, Copper Malleability/ductility

(c) Hammer head Medium Carbon Steel Toughness/hardness

(d) Knife blade Stainless steel Non-corrosive/hardness/easy to cold work

8 x 1/2= 4 marks

5. (a) (i) Clogging of a file by metal chips

(ii) Applying chalk on the surface

(iii) Cleaning using a file card or wire brush

3 x 1= 3 marks

(b)

Allows filing one surface of a shoulder or inner corner 2 marks

6. (a) LEG VICE

Enhanced rigidity hence withstands heavy blows

Capable of opening more hence holds Wider work piece

Withstands very high temperatures Any 2 x 1 = 2 marks

(b) Slide the rule through the slot in the centre head and lock. Hold the centre head against the end of the bar

Scribe a line across the end of the bar

Rotate the bar and scn'be another line to obtain a centre of intersection/bar

4 x 1/2 = 2 marks

7 (a) Forms:

Rod, wire, strip, powder Any 2 x 1/2 =

1 mark

(b) Reason:

To cater for - thickness of material being brazed

- the design of the joint

- method of heating the metal

Any 1 x l= 1 mark

8. (a) Welding

The process of joining metals by heating them to melt and fusing together.

(b) Rightward Welding

Deeper penetration and faster

Rate of cooling is reduced hence better results

Less gas is used

No berel is required for steels up to 8.0 mm thus less filler metal required/used..

Any 2 x 1= 2 marks

9. Oil Blacking

Clean the surface

Heat to red hot

Dip in clean thick oil

Heat again to

Allow to cool

bum excess oil

Clean the surface

10.

11.

12. (a) (i) Scribe the centre line using a scriber

Step off the 75mm hole centres using dividers

Dot punch hole centres using hammer and punch

Scribe 18 mm radius using dividers and rule

Scribe 25 mm radius using rule and dividers

Join 18 mm and 25 mm radii tangentially using rule and scriber

Drills holes Q 18 and Q 25 using a drill bit.

Cut along the outline using a hacksaw

File the outline smooth using a file.

6 x 1= 6 marks

(b) (i) Pop-Rivet

(ii) Steps

Mark and drill the plates

Debur the plates

Align the holes 3 x 1/2: 1 1/2 marks

(iii) Insert the rivets into the work piece and grip the pin with the rivet gun.

Press the gun to pull the pin causing the head to expand the body.

Continue pressing the gun until the pin breaks off.

3 x 1= 3 marks

Any 2 sketches X 1= 2 marks

13.(a) Anvil

(b) (i) Length of the material

Inner radius 18

Outer radius 18 + 918 + 3) 1/2,

Mean radius Q = 42/2 = 21

Length of curvature = 2nr/4 (2 x 22/7 x 21) 1/4 = 33 mm

4 X 1/2 marks

(ii) Radiuses Bend

Obtain a suitable template/jig for Q 36 or R 18

Mark the area to be bent

Heat the area to be bent

Clamp Work piece against the jig

Bend to shape.

5 x 1/2 = 2 1/2 marks

Total = 3 1/2

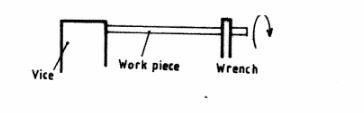

Twisting

Heat the area to be twisted

Grip firmly in the vice one end of area to be twisted

Hold the other end with tongs or wrench

Twist the bar 90° or 180°

Total 3

Bending

Mark section to be bent

Heat the section to be bent

Hold in the vice

Bend at 90°

14. (a)

(b) Procedure:

- Clean the surface to be soldered, with abrasive cloth

- Clean the soldering bit with a file

- Tin the soldering bit - heat the soldering bit until it is brown

- apply flux to the point

- add solder to the point

- Tin the surfaces separately i.e. apply flux

- heat

- apply solder

- Put the surfaces to be joined together and press firmly.

- Heat the joint using any suitable heat source e.g. soldering iron,

Gas torch or blow lamp etc; until the solder melts.

- Let the joint cool while still applying pressure.

- Clean the joint to remove any excess flux.

8 x 1 = 8 marks

(c) Safety rules

(i) Keep the hot iron away from the body.

(ii) Do not put the hot soldering iron on a wooden bench.

(m) Liquid flux is corrosive and must be kept away from eyes.

(iv) Do not touch a newly soldered joint - The joint may still be hot.

4 x 1/2 = 2 marks

(d) (i) Copper conducts heat very well.

(ii) Copper retains heat for a long time.

(iii) Copper picks up solder very easily.

3 x l= 3 marks

15. (a) Welding torch

Safety precautions

- Ensure that the nozzle seat and threads are free from any foreign materials.

- Nozzle should only be cleaned with tip cleaner

- Never use nozzle to hold or push the Work piece

- Avoid knocking nozzle against hard surfaces

Any 3 x 1 = 3 marks

(b). Gas welding flames

(i)

(ii) 1. Neutral Flame has equal quantities of oxygen and acetylene

2. Carbunsing flame has more acetylene gas than oxygen

3. Oxiding flame has more as oxygen than acetylene gas

3 x 1

Kenya Scholarships for Undergraduate Students » Kenya Scholarships for Postgraduate Students » Undergraduate Scholarships for Kenyan Students » Kenya Undergraduate Scholarships » Full Undergraduate Scholarships for Kenyans » Kenya Postgraduate Scholarships » Scholarships & Grants » Undergraduate Scholarships » Universities in Kenya » Kenya Universities and Colleges Central Placement Service (KUCCPS) » Colleges in Kenya » KASNEB Registration & Results » Secondary Schools Scholarships in Kenya » Undergraduate & Graduate Scholarships for Kenyans

Scholarships for African Students » Undergraduate Scholarships » African Women Scholarships & Grants » Developing Countries Scholarships » Erasmus Mundus Scholarships for Developing Countries » Fellowship Programs » Funding Grants for NGOs » Government Scholarships » LLM Scholarships » MBA Scholarships » PhD and Masters by Research Scholarships » Public Health Scholarships - MPH Scholarships » Refugees Scholarships » Research Grants » Scholarships and Grants

Scholarships in Australia » Scholarships in Belgium » Scholarships in Canada » Scholarships in Germany » Scholarships in Italy » Scholarships in Japan » Scholarships in Korea » Scholarships in Netherlands » Scholarships in UK » Scholarships in USA

Scholarship 2026/27

Current Scholarships 2026/2027 - Fully Funded

Full Undergraduate Scholarships 2026 - 2027

Fully Funded Masters Scholarships 2026 - 27

PhD Scholarships for International Students - Fully Funded!

Funding Opportunities for Journalists 2026/2027

Funding for Entrepreneurs 2026/2027

***