KCSE Past Papers 2017 Power Mechanics Paper 1

Click Here - Free KCSE Past Papers » KCSE Past Papers 2017 Power Mechanics Paper 1 » Free Downloads » KCSE Papers & Marking Schemes

2017 Power Mechanics - Paper 1

Section A (40 marks)

Answer all the questions in this section in the spaces provided.

1. (a) Explain the meaning of integrity. (1 mark)

(b) Outline six characteristics that distinguish entrepreneurs from ordinary business people. (3 marks)

2. (a) State two safety precautions that should be observed when using electrical hand tools. (2 marks)

(b) John intends to construct a plain scale whose representative fraction is 1:5, to read a minimum of 10 mm and a maximum of 800 mm. Calculate the length of the scale. (2 marks)

3. (a) Identify four cleaning tools used in a power mechanics workshop. (2 marks)

(b) State the purpose of the following locking devices.

(i) Grub screw

(ii) Pal nut (2 marks)

4. (a) Explain the effect of adding the following alloys to steel.

(i) Tungsten (2 marks)

‘’ (ii) Chromium

(b) Identify four areas in a motor vehicle where motors and generators are applied as energy convertors. (2 marks)

5. (a) Explain the difference between an undersquare engine and an oversquare engine. (2 marks)

(b) List four causes of cylinder wall wear. (2 marks)

6. (a) List four components that must be disconnected from a multi-cylinder engine before it is disassembled. (2 marks)

(b) Identify four types of mechanical force transmitters used in motor vehicles. (2 marks)

7. (a) Explain the importance of:

(i) Inlet valve lead.

(ii) Exhaust valve lag.

(b) State two advantages of using water as a coolant in multi-cylinder engines. (2 marks)

8. (a) State two advantages of a tungsten halogen lamp over the conventional filament lamps. (2 marks)

(b) (i) Define Castor Angle.

(ii) State the importance of Castor Angle in steering. (1 mark)

9. (a) List two types of wheels used by heavy commercial vehicles. (1 mark)

(b) (i) Explain the meaning of backfiring during oxy-acetylene welding. (1 mark)

(ii) State two causes of backfiring during oxy-acetylene welding. (2 marks)

10. (a) State two desirable characteristics of an effective brake drum. (2 marks)

(b) Identify two forces that acts on a leaf spring due to the action of the driving axles. (2 marks)

Section B (60 marks)

Answer question 11 on A3 paper and any other THREE questions from this section in the spaces provided.

Candidates are advised to spend not more than 25 minutes on question 11.

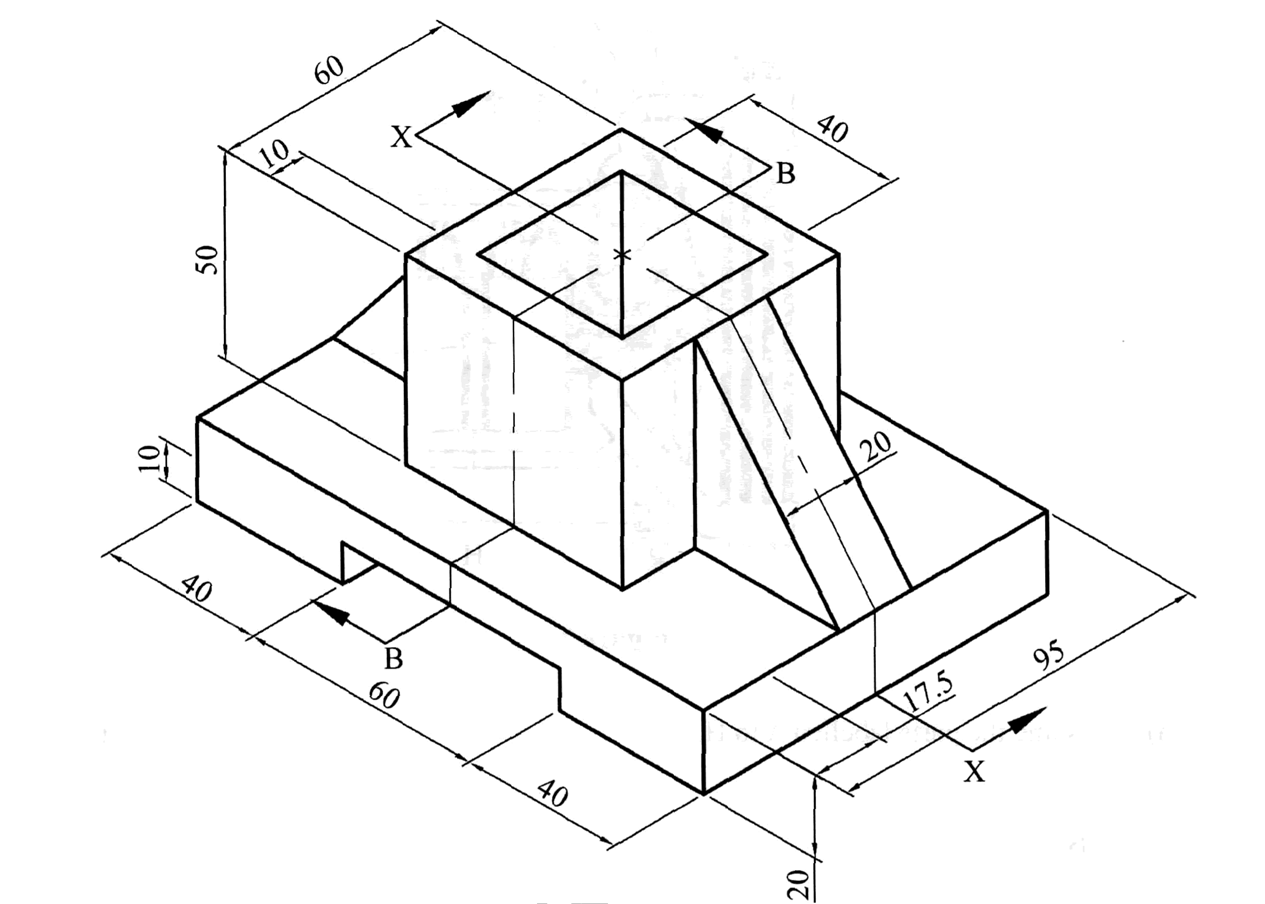

11. Figure 1 shows a block drawn in isometric projection.

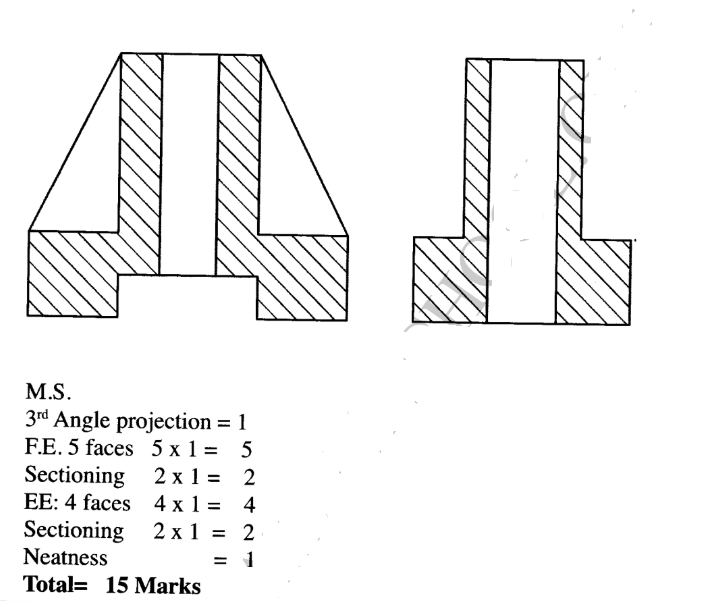

Draw full size in third angle projection the following veiws:

(a) sectional front elevation along the cutting plane X—X

(b) sectional end elevation along the cutting plane B—B (15 marks)

Figure 1

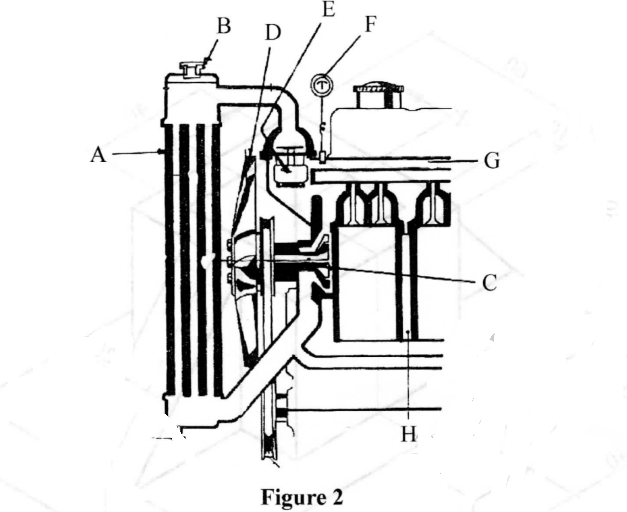

A

B

c

D

E

G

H

(b) Explain how the system works. (4 marks)

(11 marks)

13. (a) Outline three factors that are used to determine the type of an internal combustion engine. (3 marks)

(b) Explain six operational differences between 2-stroke and 4-stroke cycle petrol engines. (12 marks)

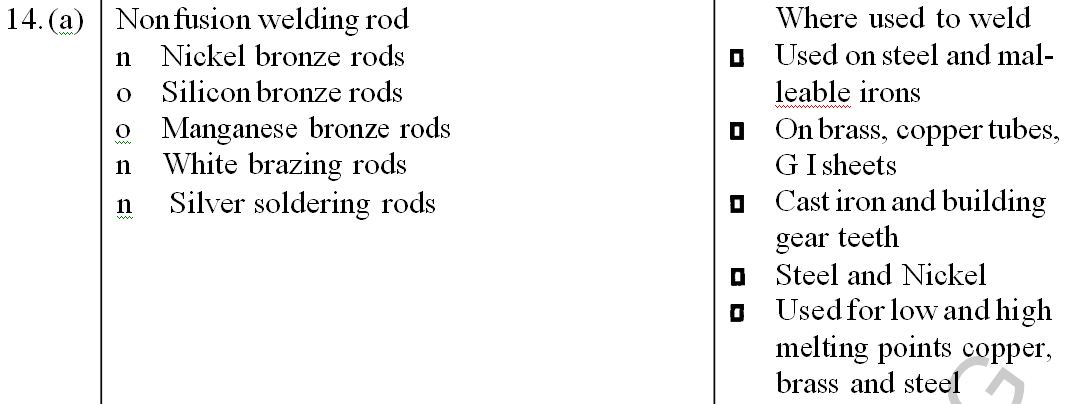

14. (a) Name five types of non-fusion welding rods and in each case, identify one material they are used to weld in motor vehicles. (5 marks)

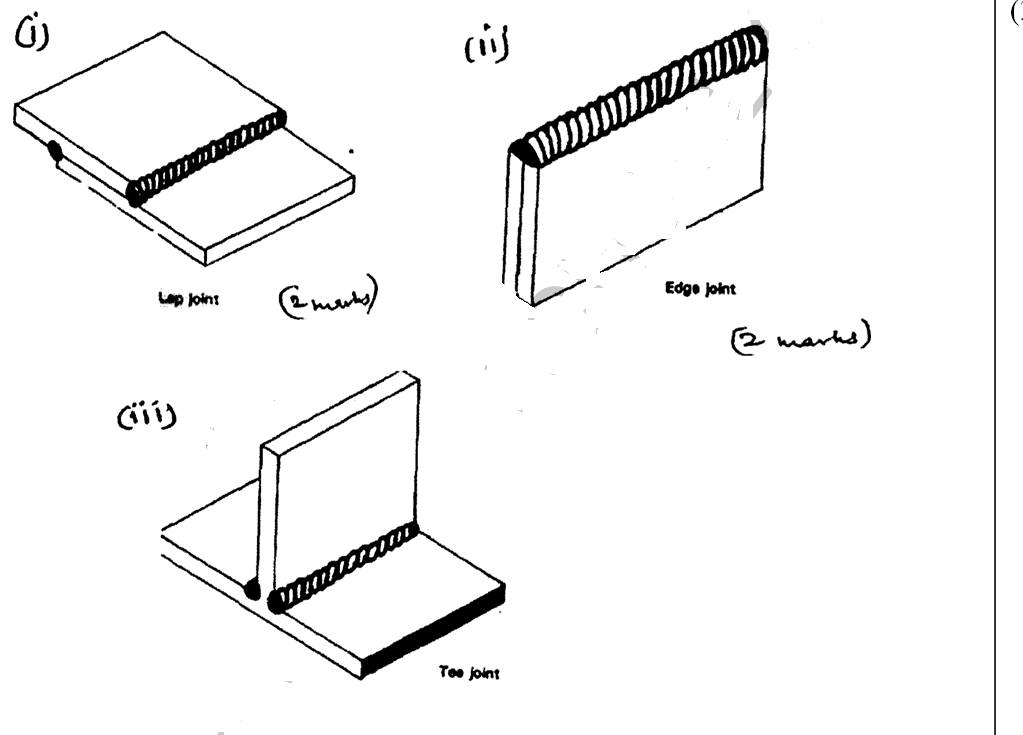

(b) With the aid of diagrams illustrate the following types of soldered joints. (6 marks)

(i) lap

(ii) edge

(iii) tee

(c) Explain two difficulties experienced when welding cast iron. (4 marks)

15. (a) Identify four possible causes of each of the following engine problems. (8 marks)

(i) Engine stalls after idling or slow speed driving.

(ii) Engine backfires

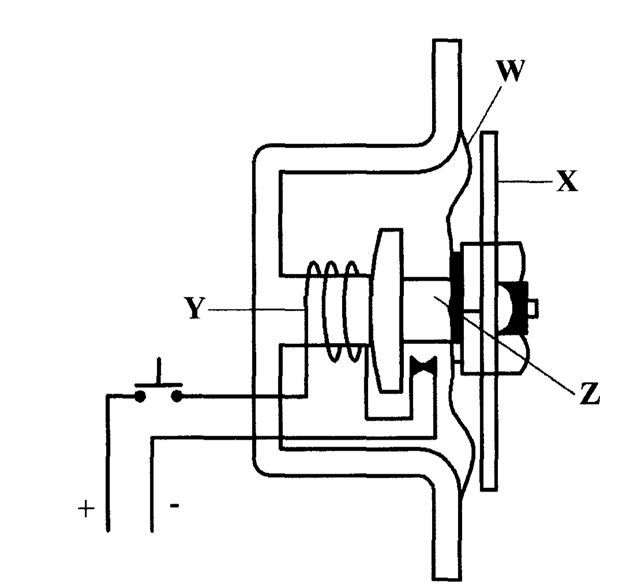

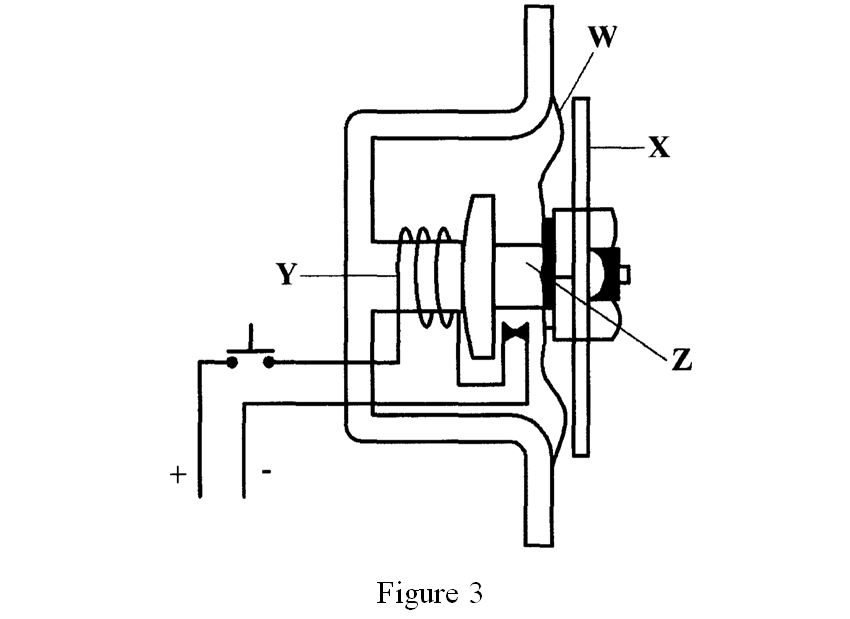

(b) Figure 3 shows the horn circuit.

(ii) Explain how the circuit operates.

Marking Scheme

KCSE Past Papers 2017 Power Mechanics Paper 1

Integrity — steadfast adherence to a strict moral or ethical code or pureness or uprightness

(b)

2. (a) Ensure the plug is properly and safely connected to the tool.

Scale length = Representative fraction x Maximum reading 1/5x 800 = l60mm 1/5 x 800 = l60mm

3. (a) Cleaning tools

(b) i. Grub screw

Often used with keys to prevent a pulley from moving along a shaft.

ii. Pal nut

Is a single threaded nut used lock another nut to prevent it from working loose.

4. (a) i. Tungsten — increases hardness

ii. Chromium — increases strength and hardness (b)b)

Wipers - (Motor)

5. (a)Undersquare engine

Is one where the bore is smaller than the stroke. Therefore the piston travels longer distance per minute to cover a stroke, and thus travels at a higher speed to cover a given RPM.

Oversquare engine

Is one where the bore is larger than the stroke. Therefore, the piston travels a shorter distance per minute to cover a stroke, and thus travels at a lower speed to cover a given RPM.

(b) Causes of cylinder wall wear (2 marks)

Abrasive material from lubricating oil.

6. (a) Battery Radiator Air cleaner Start motor Bell housing

(b) Levers and cables Belts and pulleys Wheels and pulleys Chairs and sprockets Gears Clutches

7. (a) 1. Inlet valve lead

This early opening gives as long as possible time for the intake of fresh charge into the cylinder.

2. Exhaust valve lag

Gives adequate time for the exhaust gases to be cleared from the cylinder.

(b)

8.

(b) i. Castor angle

Is the tilt of the spindle pivot towards the front or the rear of the vehicle from the vertical axis.

ii. It plays an important role in self—centering of the wheels after cornering.

9. (a) Flat base — two piece rim. Flat base divided rim.

Flat base — three piece rim. Semi-drop center rim

(b) i. Backfiring during welding procedures refers to when the flame goes out, producing a loud snapping or popping noise at the nozzle.

10. (a)

(b)

11.

B — Filler cap

C — Water pump/cylinder wall

D — Fan

E — Thermostat

F — Temperature gauge

G — Upper water gallery

H — Water jacket

(b) Operation

When the car starts, the engine is cold and the thermostat shuts off the flow of water to the radiator(1).

Since the water is confined to flow within the engine, it heats quickly as the engine runs hot.

When water reaches a pre-determined temperature, the thermostat opens, allowing free flow of coolant.(')

The hot water leaves the engine through the upper hose to the radia- tor 1).

In the radiator, it passes through the radiator core tubes, which are surrounded by cooling fins,(')through which air is drawn inwards by the low pressure vacuum(' created by the revolving fan(' .

This air cools the hot water as it passes down the radiator core(1).

The cooled water is then drawn into the engine by the water pump ') through the radiator return pipe()1 into the water jackets surrounding(' the cylinders to cool the engine block.

When there is excessive pressure build up in the system, the radiator cup equalizes the internal system pressure with the atmospheric pressure.'

13. (a)

(b) Operational differences between 2 — stroke and 4 stroke cycle engines 2 Stroke 4 Stroke

The uneven expansion and contraction caused by local heating often makes it to crack. This fault is due to the fact that most cast irons are normally in cast forms.

i. Engine stalls after idling or slow speed driving

and High carburetor float level

i. Engine backfires

When the push button is pressed, current flows through the contact points to the electromagnetic coil.

The coil gets energized(1 and attracts the armature,') which moves together with the diaphragm ')which is attached to it. When the armature is attracted, the contact points open, )1 breaking the flow of current.

The coil is the de-energized, thus making armature to be released, 1 And to move back closing the points to start the procedure again.

Kenya Scholarships for Undergraduate Students » Kenya Scholarships for Postgraduate Students » Undergraduate Scholarships for Kenyan Students » Kenya Undergraduate Scholarships » Full Undergraduate Scholarships for Kenyans » Kenya Postgraduate Scholarships » Scholarships & Grants » Undergraduate Scholarships » Universities in Kenya » Kenya Universities and Colleges Central Placement Service (KUCCPS) » Colleges in Kenya » KASNEB Registration & Results » Secondary Schools Scholarships in Kenya » Undergraduate & Graduate Scholarships for Kenyans

Scholarships for African Students » Undergraduate Scholarships » African Women Scholarships & Grants » Developing Countries Scholarships » Erasmus Mundus Scholarships for Developing Countries » Fellowship Programs » Funding Grants for NGOs » Government Scholarships » LLM Scholarships » MBA Scholarships » PhD and Masters by Research Scholarships » Public Health Scholarships - MPH Scholarships » Refugees Scholarships » Research Grants » Scholarships and Grants

Scholarships in Australia » Scholarships in Belgium » Scholarships in Canada » Scholarships in Germany » Scholarships in Italy » Scholarships in Japan » Scholarships in Korea » Scholarships in Netherlands » Scholarships in UK » Scholarships in USA

Scholarship 2026/27

Current Scholarships 2026/2027 - Fully Funded

Full Undergraduate Scholarships 2026 - 2027

Fully Funded Masters Scholarships 2026 - 27

PhD Scholarships for International Students - Fully Funded!

Funding Opportunities for Journalists 2026/2027

Funding for Entrepreneurs 2026/2027

***