Types of Disc Ploughs

Disc ploughs are of two types

(i) Standard disc plough and

(ii) Vertical disc plough.

1. Standard disc plough

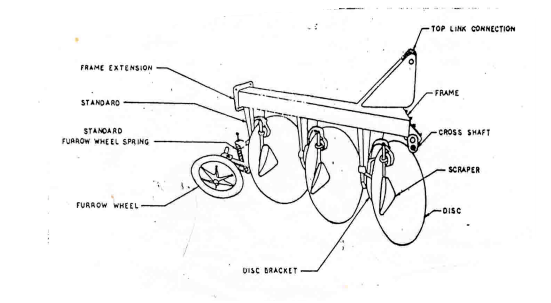

A standard disc plough consists of a series of individually mounted, inclined disc blades on a frame supported by wheels.

These ploughs usually have from 2 to 6 disc

blades, spaced to cut 18 to 30 cm per disc.

Each disc revolves on a stub axle in a thrust

bearing, carried at the lower end of a strong standard which is bolted to the plough beam

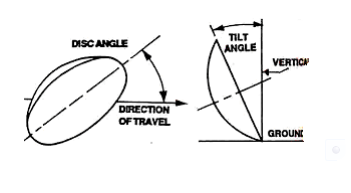

The discs are tilted backward at an angle of 15 – 25º from the vertical (tilt angle) and with a horizontal diameter disc face angle of 42 – 45 º (disc angle) from the direction of

travel.

Disc diameters are commonly 60 – 70 cm. In action, the discs cut the soil, break it and push it sideways.

There is little inversion of furrow slice as well as little burying of weeds and trashes compared to mouldboard plough.

Scrapers are furnished as regular equipment on most standard disc ploughs which assist in covering trash and prevent soil build up on discs in sticky soils.

Disc ploughs are most suitable for conditions under which a mouldboard plough do not work satisfactorily, such as in hard, dry soil, in sticky soils where a mould board will not scour, and in loose push type soil such as peat lands.

(A mouldboard plough in soils and moisture conditions where it works satisfactorily does a better job than a disc plough and has a low specific graft)

A few important terms connected with disc plough are explained below

Disc: It is a circular, concave revolving steel plate used for cutting and inverting the soil.

Disc angle: It is the angle at which the plane of the cutting edge of the disc is inclined to the direction of travel .

Usually the disc angle of good plough varies between 42° to 45°.

Tilt angle: It is the angle at which the plane of the cutting edge of the disc is inclined to a vertical line.

The tilt angle varies from 15° to 25° for a good plough.

Scraper: It is a device to remove soil that tends to stick to the working surface of a disc.

Concavity: It is the depth measured at the centre of the disc by placing its concave side on a flat surface.

Angle

Adjustments in disc plough

To obtain proper degree of pulverization and depth of cut there are certain adjustments to be made n the disc plough as follows

1. Increase the tilt angle to increase penetration ( depth of cut)

2. Increase the disc angle to increase the width of cut.

But increasing disc angle will reduce the depth of cut

3. Addition of weights on the plough will increase the penetrations

4. Keep the disc edges sharp.

This will reduce the draft requirement Adjust the plough wheels properly to keep the plough running level

2. Reversible disc plough

It is similar to standard disc plough , except that it can turn over the furrow slice to left or right side.

It not only improves the rate of work but also leaves the field flat and level.

This plough is found very successful for contour ploughing because the operation can be performed back and forth on the contour line without any problem.

The soil is turned in the direction required to prevent soil erosion.

Slopes can also be gradually leveled just by ploughing down the slope every year.

It saves water and time , improves irrigation efficiency and ensures an even crop growth and no water wastage.

The disc are rotated from one side to another by using a lever.

_________________

(Pdf) Effect of Disc and Tilt Angles of Disc Plough on Tractor

(Pdf) Testing of Tillage Emplements: Disc Plough

Advantages of Disc Plough

Can You Disc Wet Ground?

Can You Over Till a Garden?

Can You Plant a Garden Without Tilling?

Can You Plant Immediately After Tilling?

Can You Till With a Cultivator?

China Heavy Duty Round Tube Disc Plough

Chisel Plough

Components of Disc Plough

Disadvantages of Disc Plough

Disc Harrow

Disc Harrow - Wikipedia

Disc Plough

Disc Plough - Definition of Disc Plough

Disc Plough Adjustments

Disc Plough Diagram

Disc Plough Parts and Their Functions

Disc Plough Pdf

Disc Plough Wikipedia

Disc Plough Works in Which Soil

Disc Ploughing Well Labelled

Disc Plow for Sale | Economic One Way Disc Plough

Disc Plow Vs Disc Harrow

Do I Need to Remove Weeds Before Tilling?

Do You Cultivate or Plow First?

Do You Push or

Does a Tiller Remove Weeds?

Does Tilling Cause More Weeds?

Draw and Label the Disc Plough - Pdf

Farm Machinery and Equipment

Farm Power and Machinery

Function of Disc Harrow

Function of Disc Plough

Function of Furrow Wheel in Disc Plough

Functions of Parts of Disc Plough

Furrow Wheel Function

Hand Plough

How a Disc Plough Works?

How Cultivation Affects Soil

How Deep Do You Chisel Plow?

How Deep Does a Tiller Dig?

How Deep Should You Plough?

How Deep Should You Plow a Field?

How Deep Should You Till Your Garden?

How Deep Will a Subsoiler Dig?

How Do Farmers Plow Straight Lines?

How Do I Start a Ploughing Field?

How Do You Manually Plough a Field?

How Do You Plow a Field?

How Do You Plow by Hand?

How Do You Prepare a Garden Without a Tiller?

How Do You Speak Plough?

How Do You Till a Garden for the First Time?

How Do You Use a One Bottom Plow?

How Do You Use a Plough?

How Do You Use a Potato Plow?

How Does a Disc Plough Work?

How Long After Plowing Do I Wait to Disc?

How Long After Tilling Can I Plant Grass?

How Many Types of Plough Are There?

How Much Horsepower Do I Need for 2 Bottom Plow?

How Much Horsepower Does It Take to Pull a Ripper?

How Much Horsepower Does It Take to Pull a Two Bottom Plow?

Is Disking the Same as Tilling?

Is It Better to Till Wet or Dry?

Is the Plow Still Used Today?

Labelled Diagram of a Disc Plough

Labelled Diagram of a Disc Plough - Largest Pdf

Maintenance of Disc Plough

Mention the Types of Plough Class 8

Mould Board Plough

Mouldboard Plough

Mouldboard Plough Parts and Their Functions Pdf

Parts of a Disc Plough and Their Functions Pdf

Parts of a Mouldboard Plough and Their Functions

Parts of Disc Plough

Plough - Wikipedia

Should I Till or Aerate?

Should You Till Before Planting Grass?

Should You Till Your Garden Every Year?

Standard Disc Plough

Tillage and Its Implements

Types of Disc Harrow

Types of Disc Plough

Types of Plough

Types of Plough Pdf

Types of Plough With Pictures

Uses of Disc Harrow

What Are Furrows Used for?

What Are the Advantages of Bbf?

What Are the Different Methods of Ploughing?

What Are the Functions of Plough?

What Are the Methods of Ploughing?

What Are the Parts of a Disc Plough?

What Are the Tools Used for Ploughing?

What Are the Two Parts of Plough?

What Are the Uses of Disc Plough?

What Comes First Plowing or Cultivating?

What Does a 3 Point Cultivator Do?

What Does a Sub Soiler Do?

What Does Subsoiling Mean?

What Is a Dead Furrow?

What Is a Middle Buster Plow Used for?

What Is a Mouldboard Plough?

What Is a Plough?

What Is a Rotary Plough?

What Is a Tilling?

What Is Broad Bed Furrow?

What Is Chisel Plough?

What Is Disc Harrow

What Is Furrow Method?

What Is Mb Plough and Its Function?

What Is Mb Plough?

What Is Mean by Ploughing?

What Is Mole Drainage?

What Is Plough Tool?

What Is Plough Used for?

What Is Ploughing and Its Advantages?

What Is Ploughing in Agriculture?

What Is the Benefit of Deep Ploughing?

What Is the Difference Between a Chisel Plow and a Cultivator?

What Is the Difference Between a Cultivator and a Plow?

What Is the Difference Between a Cultivator and a Rotavator?

What Is the Difference Between a Cultivator and a Tiller?

What Is the Difference Between Disc Plough and Disc Harrow?

What Is the Difference Between Ploughing and Tilling?

What Is the Function of a Disc Plough?

What Is the Structure of Plough?

What Is Tilling of Soil?

What Was Life Like Before the Steel Plow?

What Was Used Before the Steel Plow?

When Should You Plow a Field?

When Should You Plow Fields?

When Was the First Plow Invented in Mesopotamia?

When Would You Use a Moldboard Plow?

Which Angle of the Disc in Disc Plough Helps for the Width of Cut?

Which Direction Do You Plow a Field?

Which One of the Following Is the Disc Angle of a Plough?

Who Invented John Deere?

Who Invented the First Plow?

Who Invented the Moldboard Plow?

Why Do Farmers Plow at Night?

Why Is It Called a Moldboard Plow?

Why Is the Plow So Important?

Why Is Tilling Soil Bad?

Why Was the Steel Plow Significance?

Why Would You Deep Plow a Field?

Will a Subsoiler Help With Drainage?

Wooden Plough

Working Principle of Disc Plough

Comments for Types of Disc Ploughs

|

||

|

||

|

||

|

||

Scholarship 2026/27

Current Scholarships 2026/2027 - Fully Funded

Full Undergraduate Scholarships 2026 - 2027

Fully Funded Masters Scholarships 2026 - 27

PhD Scholarships for International Students - Fully Funded!

Funding Opportunities for Journalists 2026/2027

Funding for Entrepreneurs 2026/2027

***