Plough Accessories

There are a few accessories necessary for efficient function of the plough.

They are

(i) Jointer

(ii) Coulter

(iii) Gauge wheel

(iv) Land wheel and

(v) Furrow wheel.

a) Jointer

It is a small irregular piece of metal having a shape similar to an ordinary plough bottom.

It looks like a miniature plough.

Its purpose is to turn over a small ribbon like furrow slice directly in front of the main plough bottom.

This small furrow slice is cut from the left and upper side of the main furrow slice and is inverted so that all trashes on the top of the soil are completely turned down and buried under the right hand corner of the furrow.

b) Coulter

It is a device used to cut the furrow slice vertically from the land ahead of the plough bottom.

It cuts the furrow slice from the land and leaves a clear wall.

It also cuts trashes which are covered under the soil by the plough.

The coulter may be

(a) Rolling type disc coulter or

(b) Sliding type knife coulter.

Rolling type disc coulter

It is a round steel disk which has been sharpened on the edge and suspended on a shank and yoke from the beam.

The edge of the coulter may be either smooth or notched.

It is so fitted that it can be adjusted up-down and side ways.

The up-down adjustment takes care of depth and sideways adjustment is meant for taking care of

width of cut.

Sliding type knife coulter

It is a stationary knife fixed downward in a vertical position on the beam.

The knife does not roll over the ground but slides on the ground.

The knife may be of different shapes and sizes.

c) Gauge wheel

It is an auxiliary wheel of an implement to maintain an uniform depth of working.

Gauge wheel helps to maintain uniformity in respect of depth of ploughing in different soil conditions.

It is usually placed in hanging position.

d) Land wheel - It is the wheel of the plough which runs on the ploughed land.

e) Front furrow wheel - It is the front wheel of the plough which runs in the furrow.

f) Rear furrow wheel - It is the rear wheel of the plough which runs in the furrow.

Adjustment of Mouldboard Plough

For proper penetration and efficient work by the mouldboard plough, some adjustments are made from time to trime.

They are

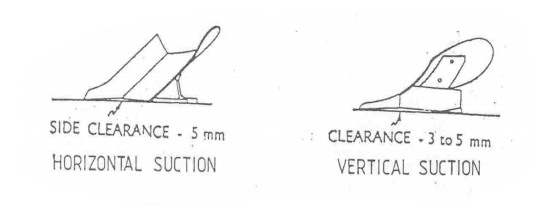

(i) Vertical suction and

(ii) Horizontal suction.

a) Vertical suction (Vertical clearance)

It is the maximum clearance under the land side and the horizontal surface when the plough is resting on a horizontal surface in the working position.

It is also defined as the vertical distance from the ground, measured at the joining point of share and land side. (Fig.7a).

It helps the plough to penetrate into the soil to a proper depth.

This clearance varies according to the size of the plough.

b) Horizontal suction (Horizontal clearance)

It is the maximum clearance between the land side and the furrow wall.

This suction helps the plough to cut the proper width of furrow slice.

This clearance also varies according to the size of the plough.

It is also known as side clearance.

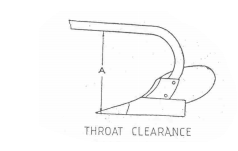

c) Throat clearance

It is the perpendicular distance between share point and lower position of the beam of the plough .

_________________________

(Pdf) Effect of Disc and Tilt Angles of Disc Plough on Tractor

(Pdf) Testing of Tillage Emplements: Disc Plough

Advantages of Disc Plough

Can You Disc Wet Ground?

Can You Over Till a Garden?

Can You Plant a Garden Without Tilling?

Can You Plant Immediately After Tilling?

Can You Till With a Cultivator?

China Heavy Duty Round Tube Disc Plough

Chisel Plough

Components of Disc Plough

Disadvantages of Disc Plough

Disc Harrow

Disc Harrow - Wikipedia

Disc Plough

Disc Plough - Definition of Disc Plough

Disc Plough Adjustments

Disc Plough Diagram

Disc Plough Parts and Their Functions

Disc Plough Pdf

Disc Plough Wikipedia

Disc Plough Works in Which Soil

Disc Ploughing Well Labelled

Disc Plow for Sale | Economic One Way Disc Plough

Disc Plow Vs Disc Harrow

Do I Need to Remove Weeds Before Tilling?

Do You Cultivate or Plow First?

Do You Push or Pull a Tiller?

Does a Tiller Remove Weeds?

Does Tilling Cause More Weeds?

Draw and Label the Disc Plough - Pdf

Farm Machinery and Equipment

Farm Power

Function of Disc Harrow

Function of Disc Plough

Function of Furrow Wheel in Disc Plough

Functions of Parts of Disc Plough

Furrow Wheel Function

Hand Plough

How a Disc Plough Works?

How Cultivation Affects Soil

How Deep Do You Chisel Plow?

How Deep Does a Tiller Dig?

How Deep Should You Plough?

How Deep Should You Plow a Field?

How Deep Should You Till Your Garden?

How Deep Will a Subsoiler Dig?

How Do Farmers Plow Straight Lines?

How Do I Start a Ploughing Field?

How Do You Manually Plough a Field?

How Do You Plow a Field?

How Do You Plow by Hand?

How Do You Prepare a Garden Without a Tiller?

How Do You Speak Plough?

How Do You Till a Garden for the First Time?

How Do You Use a One Bottom Plow?

How Do You Use a Plough?

How Do You Use a Potato Plow?

How Does a Disc Plough Work?

How Long After Plowing Do I Wait to Disc?

How Long After Tilling Can I Plant Grass?

How Many Types of Plough Are There?

How Much Horsepower Do I Need for 2 Bottom Plow?

How Much Horsepower Does It Take to Pull a Ripper?

How Much Horsepower Does It Take to Pull a Two Bottom Plow?

Is Disking the Same as Tilling?

Is It Better to Till Wet or Dry?

Is the Plow Still Used Today?

Labelled Diagram of a Disc Plough

Labelled Diagram of a Disc Plough - Largest Pdf

Maintenance of Disc Plough

Mention the Types of Plough Class 8

Mould Board Plough

Mouldboard Plough

Mouldboard Plough Parts and Their Functions Pdf

Parts of a Disc Plough and Their Functions Pdf

Parts of a Mouldboard Plough and Their Functions

Parts of Disc Plough

Plough - Wikipedia

Should I Till or Aerate?

Should You Till Before Planting Grass?

Should You Till Your Garden Every Year?

Standard Disc Plough

Tillage and Its Implements

Types of Disc Harrow

Types of Disc Plough

Types of Plough

Types of Plough Pdf

Types of Plough With Pictures

Uses of Disc Harrow

What Are Furrows Used for?

What Are the Advantages of Bbf?

What Are the Different Methods of Ploughing?

What Are the Functions of Plough?

What Are the Methods of Ploughing?

What Are the Parts of a Disc Plough?

What Are the Tools Used for Ploughing?

What Are the Two Parts of Plough?

What Are the Uses of Disc Plough?

What Comes First Plowing or Cultivating?

What Does a 3 Point Cultivator Do?

What Does a Sub Soiler Do?

What Does Subsoiling Mean?

What Is a Dead Furrow?

What Is a Middle Buster Plow Used for?

What Is a Mouldboard Plough?

What Is a Plough?

What Is a Rotary Plough?

What Is a Tilling?

What Is Broad Bed Furrow?

What Is Chisel Plough?

What Is Disc Harrow

What Is Furrow Method?

What Is Mb Plough and Its Function?

What Is Mb Plough?

What Is Mean by Ploughing?

What Is Mole Drainage?

What Is Plough Tool?

What Is Plough Used for?

What Is Ploughing and Its Advantages?

What Is Ploughing in Agriculture?

What Is the Benefit of Deep Ploughing?

What Is the Difference Between a Chisel Plow and a Cultivator?

What Is the Difference Between a Cultivator and a Plow?

What Is the Difference Between a Cultivator and a Rotavator?

What Is the Difference Between a Cultivator and a Tiller?

What Is the Difference Between Disc Plough and Disc Harrow?

What Is the Difference Between Ploughing and Tilling?

What Is the Function of a Disc Plough?

What Is the Structure of Plough?

What Is Tilling of Soil?

What Was Life Like Before the Steel Plow?

What Was Used Before the Steel Plow?

When Should You Plow a Field?

When Should You Plow Fields?

When Was the First Plow Invented in Mesopotamia?

When Would You Use a Moldboard Plow?

Which Angle of the Disc in Disc Plough Helps for the Width of Cut?

Which Direction Do You Plow a Field?

Which One of the Following Is the Disc Angle of a Plough?

Who Invented John Deere?

Who Invented the First Plow?

Who Invented the Moldboard Plow?

Why Do Farmers Plow at Night?

Why Is It Called a Moldboard Plow?

Why Is the Plow So Important?

Why Is Tilling Soil Bad?

Why Was the Steel Plow Significance?

Why Would You Deep Plow a Field?

Will a Subsoiler Help With Drainage?

Wooden Plough

Working Principle of Disc Plough

Comments for Plough Accessories

|

||

|

||

|

||

|

||

|

||

|

||

Scholarship 2026/27

Current Scholarships 2026/2027 - Fully Funded

Full Undergraduate Scholarships 2026 - 2027

Fully Funded Masters Scholarships 2026 - 27

PhD Scholarships for International Students - Fully Funded!

Funding Opportunities for Journalists 2026/2027

Funding for Entrepreneurs 2026/2027

***